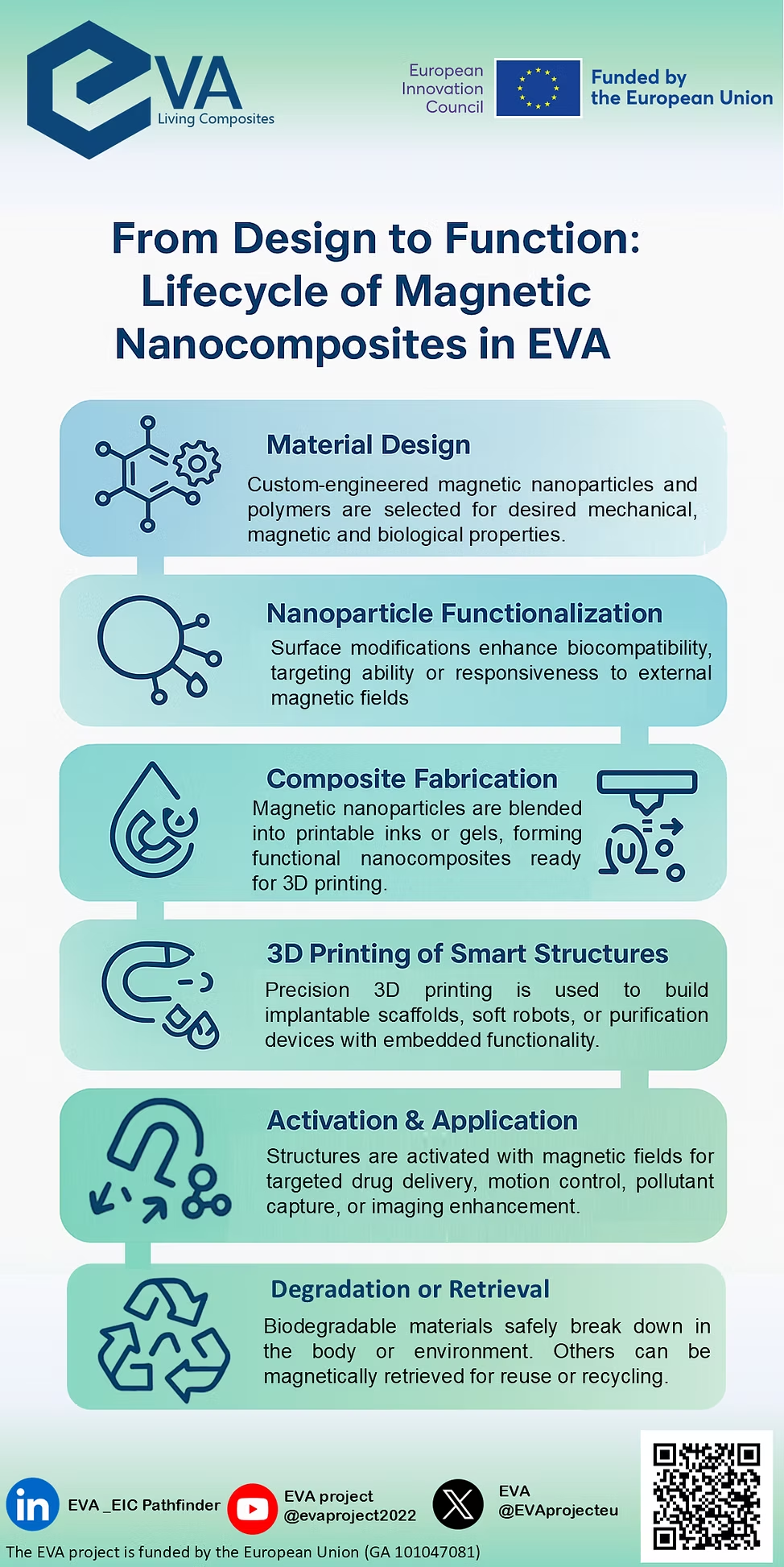

The EVA project pioneers a full-spectrum approach to the development and application of magnetic nanocomposites—engineered materials that bring together precision design, functionality, and sustainability.

At the core of our work is a carefully structured process:

-

Material Design

We begin by selecting and engineering magnetic nanoparticles and polymer matrices to achieve the desired mechanical strength, magnetic responsiveness, and biocompatibility. -

Nanoparticle Functionalization

Surface modifications enhance the nanoparticles’ ability to interact with biological systems, improve targeting precision, and respond to magnetic fields for controlled behavior. -

Composite Fabrication

These tailored nanoparticles are integrated into printable formulations—gels or inks—creating functional nanocomposites ready for advanced manufacturing. -

3D Printing of Smart Structures

Using precision additive manufacturing, we create complex architectures such as implantable scaffolds, soft robotic components, or filtration systems with embedded magnetic functionality. -

Activation & Application

Once deployed, the structures are activated using external magnetic fields to deliver targeted therapies, guide motion, enhance imaging, or capture environmental pollutants. -

Degradation or Retrieval

Finally, sustainability is built into the design: EVA materials are either biodegradable within the body or environment, or they can be magnetically retrieved for reuse or safe disposal.

This lifecycle reflects EVA’s mission: to merge advanced nanomaterials, smart manufacturing, and functional design into a single, coherent innovation pipeline that supports next-generation biomedical and environmental technologies.